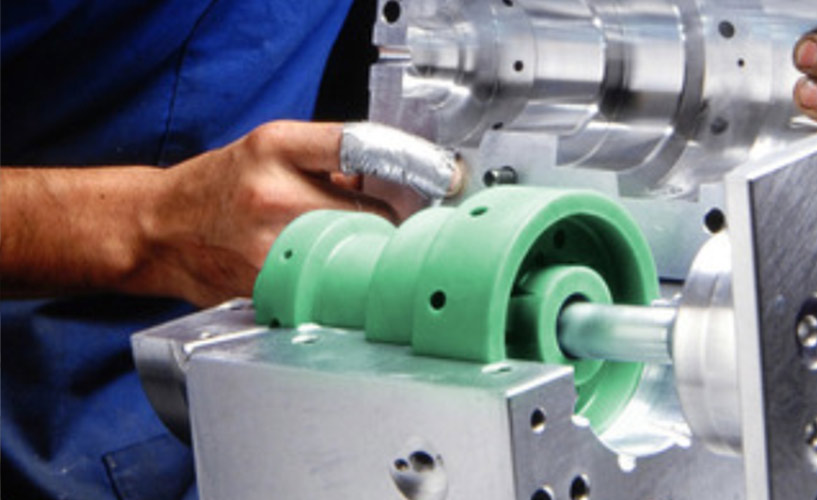

(01) Tool Development

We start the process by Crafting molds and tools to make precision components. These meticulously designed tools ensure the exact replication of intricate parts, guaranteeing accuracy and quality in the production process.

(02) Wax Pattern Manufacturing

Precision in wax pattern manufacturing is crucial as it forms the foundation for casting complex components. Accurate wax prototypes are meticulously crafted to create molds that faithfully reproduce the desired shapes and intricacies.

(03) Wax Pattern Assembly

The assembly of wax patterns demands meticulous attention to detail. Then we carefully combine individual wax elements to set the stage for precise casting processes, ensuring that every component meets the required specifications.

(04) Ceramic Coating

The application of protective ceramic layers enhances the durability and resilience of precision components. This critical step ensures that components can withstand the harsh conditions they may encounter during use, preserving their quality and performance.

(05) Dewaxing

Removing wax from molds with precision is essential to prepare them for the casting of intricate parts. This step requires meticulous handling to avoid any damage to the mold or the final product.

(06) Pre-Heating Of Shells

The controlled pre-heating of molds to optimal temperatures is vital for a successful casting process. This step ensures that the molten material flows uniformly, resulting in high-quality, defect-free components.

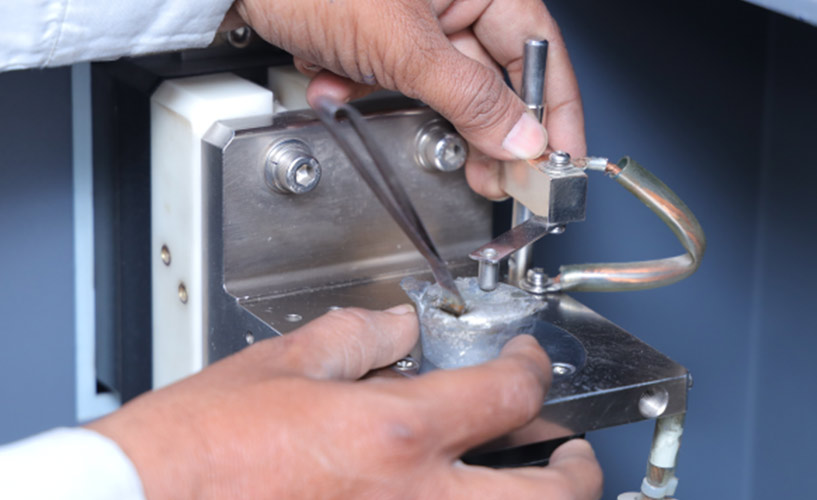

(07) Inspection Of Chemical Composition

Thoroughly analyzing the material composition is imperative to guarantee the integrity of precision components. Understanding and controlling the composition is essential for meeting performance and quality standards.

(08) Pouring

Thoroughly analyzing the material composition is imperative to guarantee the integrity of precision components. Understanding and controlling the composition is essential for meeting performance and quality standards.

(09) Knockout

Carefully extracting components post-casting is essential to safeguard their form and function. Delicate handling during this phase prevents any damage to the newly formed components.

(10) Fettling

Skillfully refining castings through techniques like grinding and cutting is necessary to achieve the desired precision and finish. This step removes excess material and imperfections, enhancing the component’s quality.

(11) Visual Inspection

Methodically examining components for imperfections is vital to uphold quality standards. Visual inspections identify any defects or irregularities that may affect the component’s performance or appearance.

(12) Heat Treatment

Applying controlled heat to enhance material properties ensures that components meet performance requirements. This step optimizes hardness, strength, and other material characteristics.

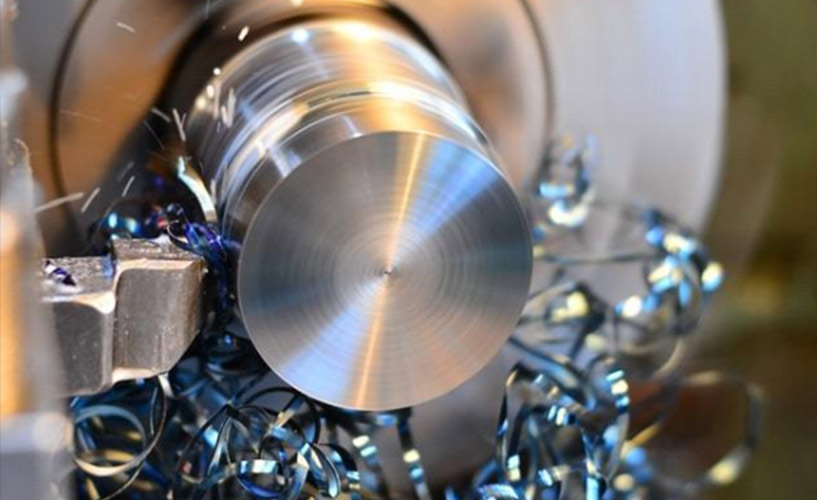

(13) Machining

Employing precision machining techniques is crucial to shape and finish components accurately. Machining ensures that components meet tight tolerances and surface finish specifications.

(14) Quality Control And Assurance

Rigorously maintaining quality standards throughout the entire process is essential. Continuous monitoring and inspection at each stage assure the reliability and consistency of every component.

(15) Final Dispatch

Thoughtfully packaging and dispatching finished components is the last step in the process. Our main aim is to meet delivery expectations and ensure that customers receive high-quality precision components on time and in optimal condition.